Lightweight Insulating Fire Bricks

Lightweight Insulating Fire Bricks are made from high-purity refractory clay and alumina, with an appropriate amount of organic fillers added. These organic fillers are burned off during the production process, resulting in a uniform pore structure. For different temperature ratings, the amount of alumina added increases with the rating.

Lightweight insulating fire bricks are lightweight and have low heat storage capacity. They also have high and uniform porosity, providing excellent insulation. They are suitable for temperatures ranging from 900°C to 1550°C.

Conforming to ASTM standards, the AB series utilizes hollow alumina spheres and alumina powder with a composite binder, which is vibrated and fired at high temperatures. Lightweight insulating fire bricks offer excellent high-temperature performance and can be safely used at temperatures up to 1550°C.

Product Features

Low thermal conductivity and excellent insulation allow for thinner furnace walls.

Low heat capacity, lightweight, and low thermal conductivity allow for minimal heat storage within the bricks, significantly reducing energy consumption in intermittently operated furnaces.

Precise dimensions and high machining accuracy ensure consistent brick joints.

Physical and chemical properties

| Classification | YK23 | YK23 | YK26 | YK28 | YK30 | YK32 | AB96 | AB98 |

| Classification temperature (°C) | 1260 | 1260 | 1400 | 1500 | 1550 | 1600 | 1650 | 1700 |

| Density (kg/m³) | 550 | 800 | 800 | 900 | 1000 | 1100 | 1350 | 1500 |

| Reburning shrinkage (%) JIS R2613 (°C×8h) |

0.3 (1260) |

0.4 (1260) |

0.4 (1400) |

0.6 (1500) |

0.6 (1550) |

0.6 (1600) |

0.4 (1650) |

0.3 (1700) |

| Compressive strength (MPa) | 1.1 | 1.8 | 1.9 | 2.5 | 2.8 | 3 | 8.5 | 9.5 |

| Flexural strength (MPa) | 0.8 | 1.2 | 1.2 | 1.4 | 1.6 | 1.8 | - | - |

| Thermal conductivity 350°C (W/m·K) | 0.15 | 0.26 | 0.26 | 0.33 | 0.38 | 0.43 | - | - |

| Thermal expansion (%) (JIS R2617, °C) | ≤0.46 | ≤0.46 | ≤0.47 | ≤0.48 | ≤0.48 | ≤0.49 | - | - |

| Chemical compositionAl₂O₃ (%) | 40% | 40% | 54% | 62% | 74% | 80% | 96% | 98% |

| Chemical compositionFe₂O₃ (%) | 1.20% | 1.20% | 0.90% | 0.80% | 0.70% | 0.50% | 0.40% | 0.40% |

| Matching putty | RM-1400 | RM-1400 | RM-1400 | RM-1600 | RM-1600 | RM-1750 | RM-1750 | RM-1750 |

Chemical composition

| Classification | B4 | B5 | B6 | B7 | C1 | C2 |

| Classification temperature (°C) | 1200 | 1300 | 1400 | 1500 | 1300 | 1400 |

| Density (kg/m³) | 780 | 780 | 890 | 960 | 1060 | 1140 |

| Reburning shrinkage (%) JIS R2613 (°C×8h) |

0.3 (1200) |

0.3 (1300) |

0.6 (1400) |

0.9 (1500) |

0.7 (1300) |

0.8 (1400) |

| Compressive strength (ASTM C93, Mpa) | 1.4 | 1.5 | 2.4 | 3.5 | 3.6 | 4 |

| Flexural strength (ASTMC93, Mpa) | 0.8 | 0.8 | 1.5 | 2 | 2.1 | 2.6 |

| Thermal expansion (%) (JIS R2617, C) | 0.5 | 0.5 | 0.48 | 0.5 | 0.5 | 0.5 |

| Al₂O₃ (%) | 41% | 41% | 41% | 62% | 40% | 41% |

| Fe₂O₃ (%) | 1.20% | 1.20% | 1.40% | 0.90% | 1.20% | 1.20% |

| Matching putty | RM-1400 | RM-1400 | RM-1400 | RM-1400 | RM-1400 | RM-1400 |

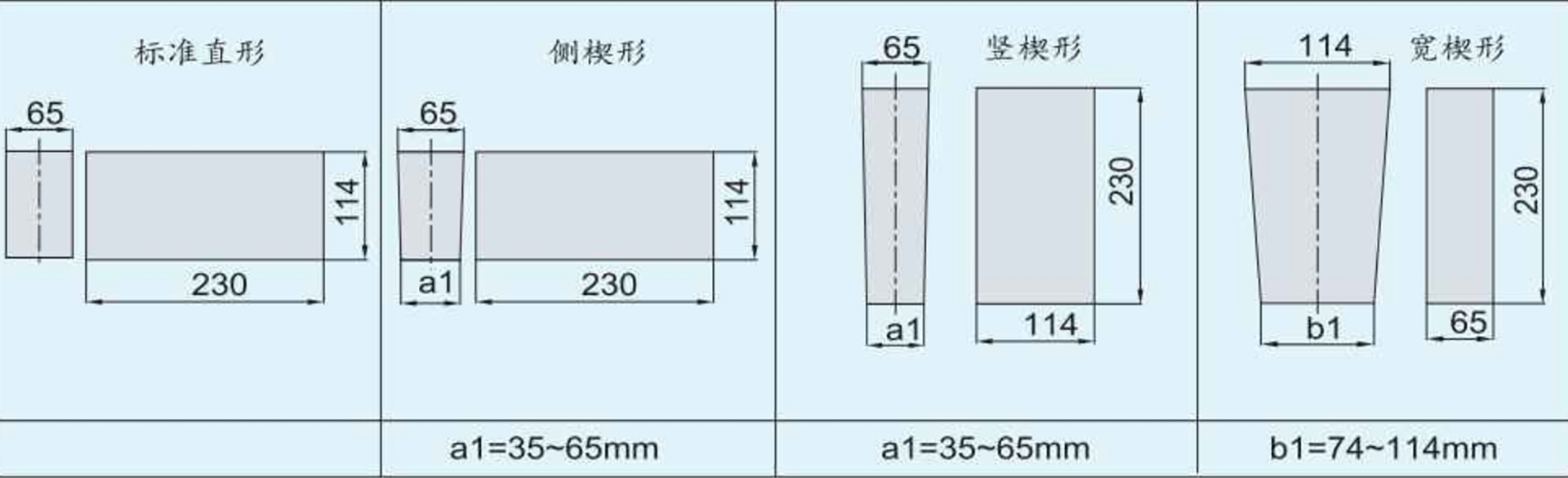

Dimensions

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى