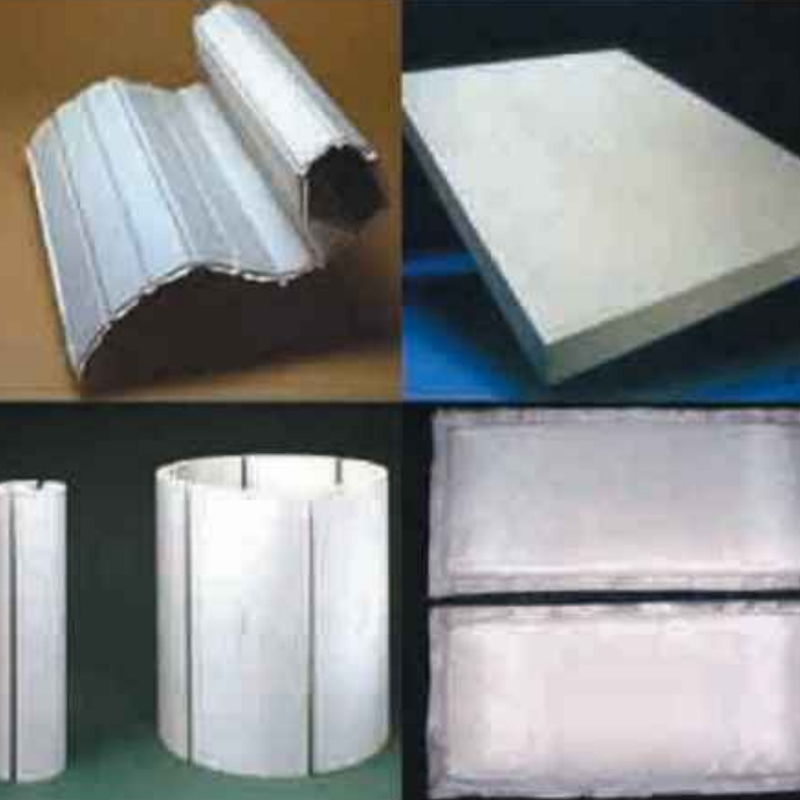

Nano Microporous Insulation Board

Nano-insulation composite materials are made by combining nanoporous materials with heat-shielding materials through a special process. Their thermal conductivity is only 114-1110% of that of conventional ceramic fiber insulation. Nano Microporous Insulation Board, a new material manufactured using the latest high-tech technology, is the best insulation material to date. Nanoboard is a high-strength insulation material with excellent thermal insulation properties, commonly used in areas requiring high-strength and high-efficiency insulation. The product comes in a sheet form and can be coated with various materials, such as aluminum foil or high-temperature cloth.

Product Features

High-temperature resistance

Low thermal conductivity

Environmentally friendly and safe

Low heat storage

Long service life

Applications

Steel and petrochemical industries

Ceramics and glass industries

Industrial furnaces

Power generation, household appliances, aerospace

A new alternative to traditional refractory and insulation materials

| Classification temperature (°C) | 1000 |

| Density (kg/m³) | 300-350 |

| Compressive strength at room temperature (MPa) | 0.7 |

| Permanent linear shrinkage% (800°C × 6h) | < 3.5% |

| Thermal conductivity (W/m·K) | 0.020(100°C) |

| 0.025(200°C) | |

| 0.028(400°C) | |

| 0.032(600°C) | |

| 0.037(800°C) |

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى