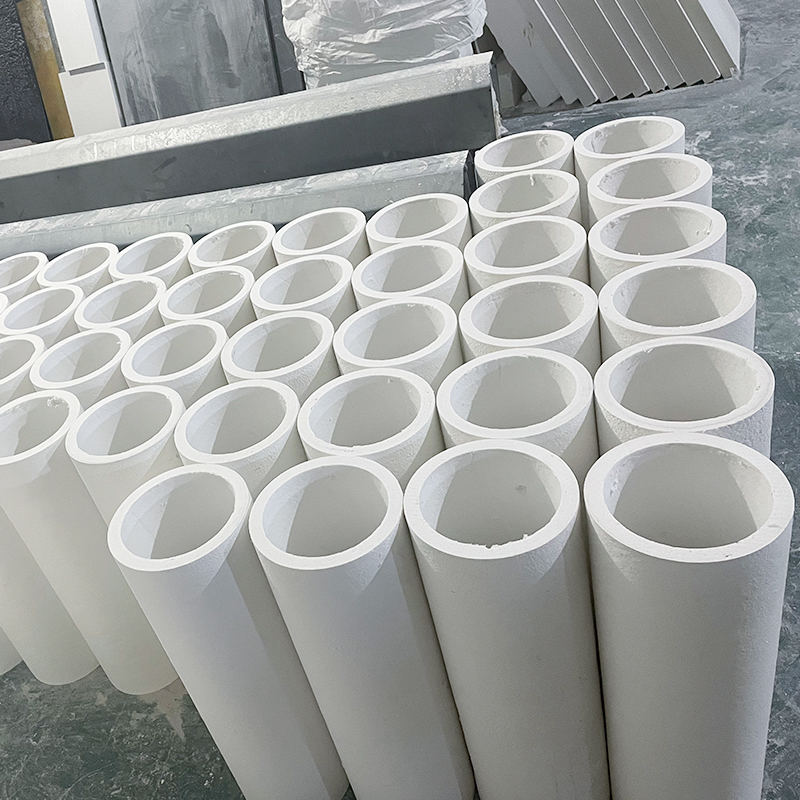

Ceramic Fiber Tube

Ceramic fiber tube is a high-performance refractory product with excellent compressive strength and bending resistance, and can withstand severe mechanical stress. Its unique low thermal conductivity can effectively reduce heat loss and significantly improve the energy efficiency of thermal equipment. The product has excellent thermal shock resistance and can withstand sudden temperature changes without cracking and deformation. Combined with the rapid heating and cooling response characteristics, it greatly improves production efficiency.

Application in High-temperature industrial equipment :

Hot surface treatment : used for hot surface parts such as burner bricks, observation holes, and electric heating element brackets, which are directly in contact with flames .

Furnace structure : Replace traditional refractory materials to construct furnace walls and expansion joints to achieve seamless furnace lining .

Applications:

1. Core components of industrial furnaces

(1) Electric heating equipment support

As an insulating support for electric heating elements, it directly bears high temperature radiation. Its low thermal conductivity (normal temperature 0.040-0.065 W/(m·K)) effectively isolates heat conduction and ensures stable operation of the equipment. Its thermal shock resistance (withstands rapid cooling and heating at ≤1200℃) can match the high-frequency start and stop requirements of the equipment.

(2) Iron and steel metallurgical insulation system

Used for hot surface components such as burner bricks and observation holes of soaking furnaces to resist flame erosion and slag erosion during the heating of steel ingots. High dimensional accuracy (wall thickness 1.5-5mm) ensures a close fit with the furnace structure and reduces heat leakage.

2. Efficient pipe insulation

(1) Steam pipe protection

As an insulation shell of an overhead steam pipe, it blocks heat loss through low thermal conductivity, maintains a stable medium temperature, and increases energy saving by more than 30%. The compressive strength is ≥0.2MPa, which can buffer the deformation stress of the pipeline.

(2) Corrosion environment protection

The special solidified layer on the surface can block the penetration of rainwater and chemical media, prevent the corrosion failure of the insulation layer, and significantly extend the life of the pipeline.

3. High temperature lining in the power industry

(1) Boiler refractory lining

Replace traditional refractory bricks to construct boiler furnace walls. The lightweight characteristics (bulk density is only 1/3 of traditional materials) reduce the load on the steel structure, and the rapid thermal response capability shortens the furnace drying time by 50%.

(2) Environmentally friendly flue gas treatment

The filter tube components used in the desulfurization and denitrification system have anti-airflow erosion characteristics to ensure stable operation in high-temperature dusty flue gas, and the filtration efficiency is ≥99.99%.

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى