Ceramic Fiber Heating Module Block for Electric Resistance Furnace

Introduction

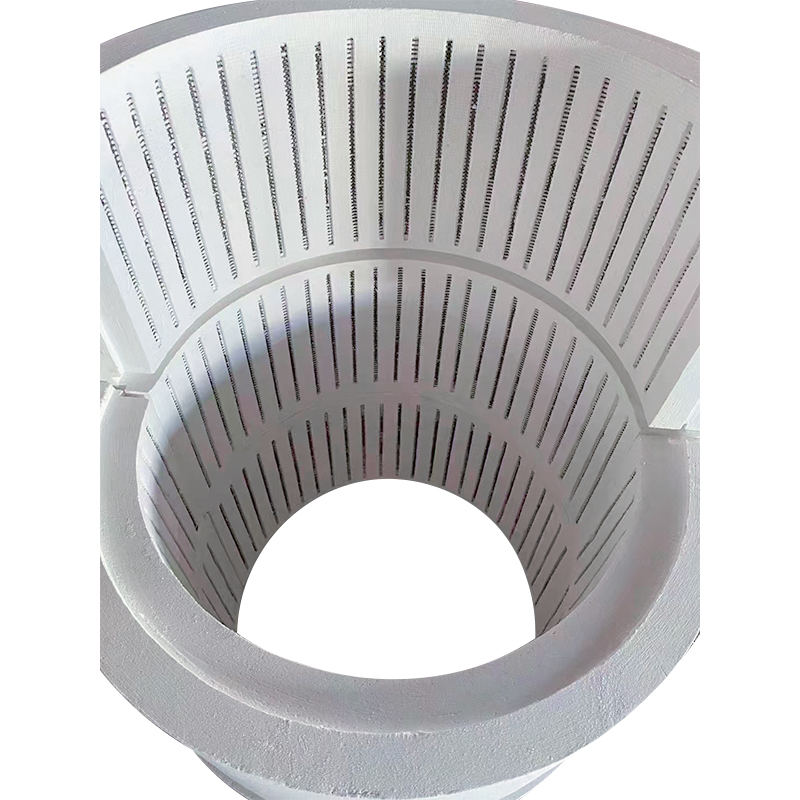

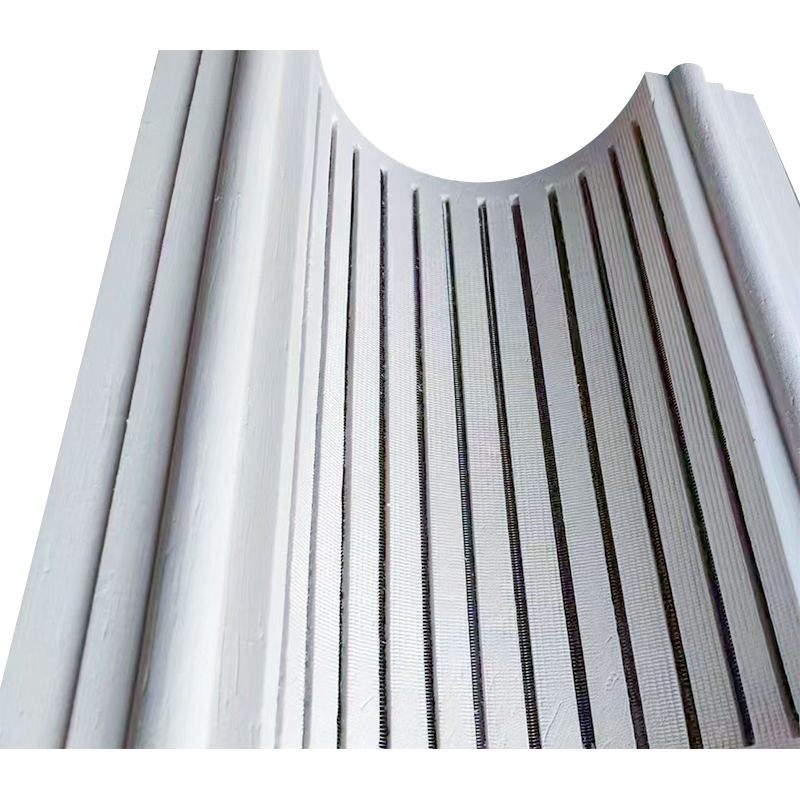

NC fiber heating module, resistance furnace product description. The NC fiber heating module is a single fiber electric heating element formed by combining the fiber material with the embedded resistance wire through a special processing technique. The resistance wire can be arranged in either a "Z" shape or a spiral shape. The forming methods include embedding and burying. It can be used at temperatures ranging from 300 to 1300°C and is an ideal alternative to traditional resistance heating equipment due to its unique advantages.

The NC high-efficiency energy-saving resistance furnace uses high-temperature refractory fiber vacuum-formed products as the furnace lining, with integrated mechanical and electrical design, program control, and digital display. It has an energy-saving rate of up to 40% and meets the national Class C furnace standard according to testing results. It has advantages such as fast temperature rise/fall speed, high temperature control accuracy, uniform furnace temperature distribution, and light weight.

Characteristics

The product features high-temperature stability, low thermal conductivity, low heat capacity, heat shock resistance, corrosion resistance, excellent insulation performance, compression/ bending resistance, and easy installation and use.

Application

The product is widely used in various types of custom-shaped resistive heaters such as tube furnaces, jet dyeing machines, circular arc heaters, pipeline heating devices,cabinet-type resistive furnaces, and large industrial electric furnaces. The common specifications of the product are designed and produced according to customer requirements.

Product Common Specifications

Designed according to user requirements.

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى