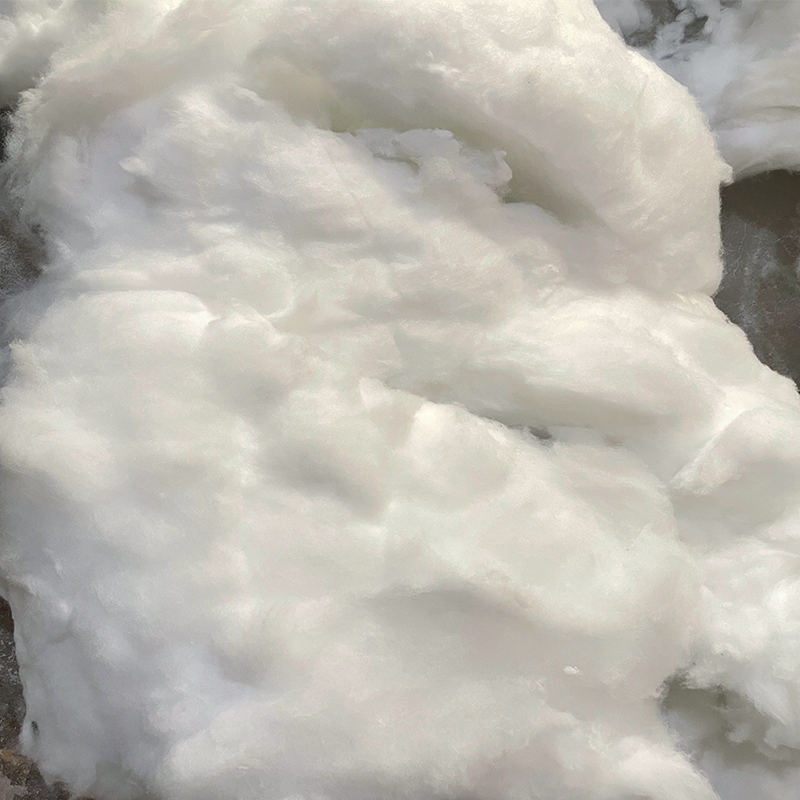

Ceramic Fiber Cotton

Introduction

NC ceramic fiber cotton is produced by melting the very pure raw materials at high temperature, taking advantage of the spun or blowing method with characteristics of stable chemical performance, resistance to most erosion of physical properties like refractoriness and insulation, keeping the same when meeting with oil, water, or steam. Ceramic fiber blanket/felt/board/paperlcloth/rope, and other ceramic fiber products can be produced in bulk through further processing.

Characteristics

NC ceramic fiber cotton is a kind of insulating material which has these characteristics, such as light-weight, antioxidation, low thermal conductivity, softness,

anti-corrosion, low heat capacity, sound insulation, and so on.

Application

Flling sealing and insulation at high temperatures(kiln car,pipeline,kilndoor,etc.);

Composite material in the fiber industry(friction plate,etc.);

Expansion joint filler material for firebricks and castable;

Filler for short-term insulation;

Thermal insulation filling material for small corners;

Raw materials for further processing.

Product parameter

| Ceramic fiber cotton | NC1260 | NC1350 | NC1400 | NC1430 | NC1600 | |

| Classification temperature (°C ) | 1260 | 1350 | 1400 | 1430 | 1600 | |

| Melting point(°C ) | 1750 | 1750 | 1750 | 1750 | ||

| Fiber average diameter (μm) | 2.6 | 2.6 | 2.5 | 2.5 | 1.95 | |

| Density(g/m3) | 2.7 | 2.7 | 2.7 | 2.7 | 3.1 | |

| Chemical composition (%) |

Al2O3 | 46-49 | 52-55 | 54-57 | 44-48 | 72 |

| Al2O3+ SiO2 | 97 | 97 | 97 | 82 | 99 | |

| ZrO3 | 15-17 | |||||

| Other | 3 | 3 | 3 | 2 | 1 | |

Note: The technical data determined by the testing standards used was, on average, within a certain range; the data do not represent the product quality assurance data.

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى