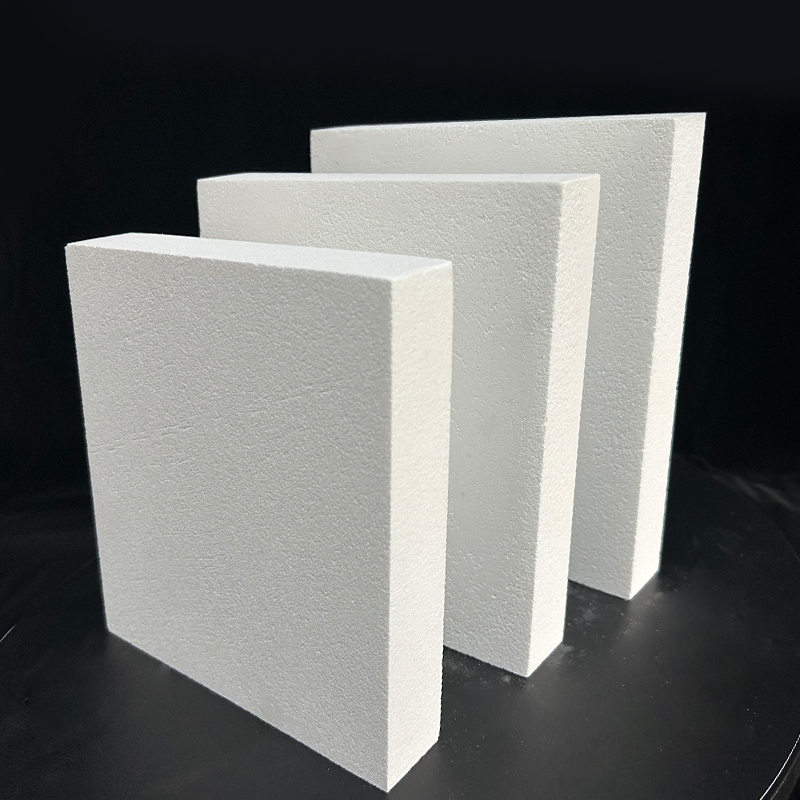

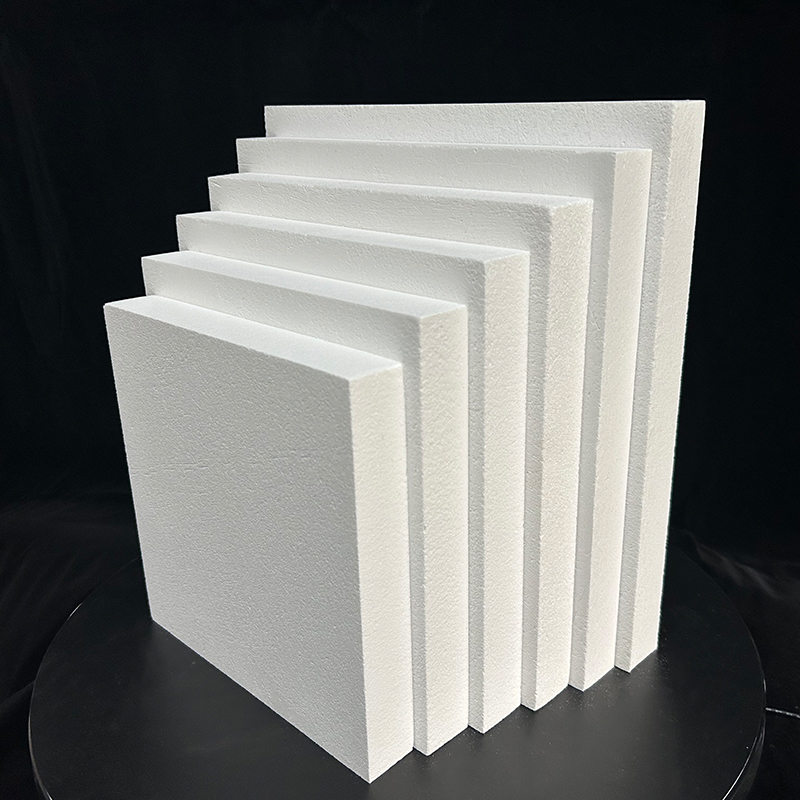

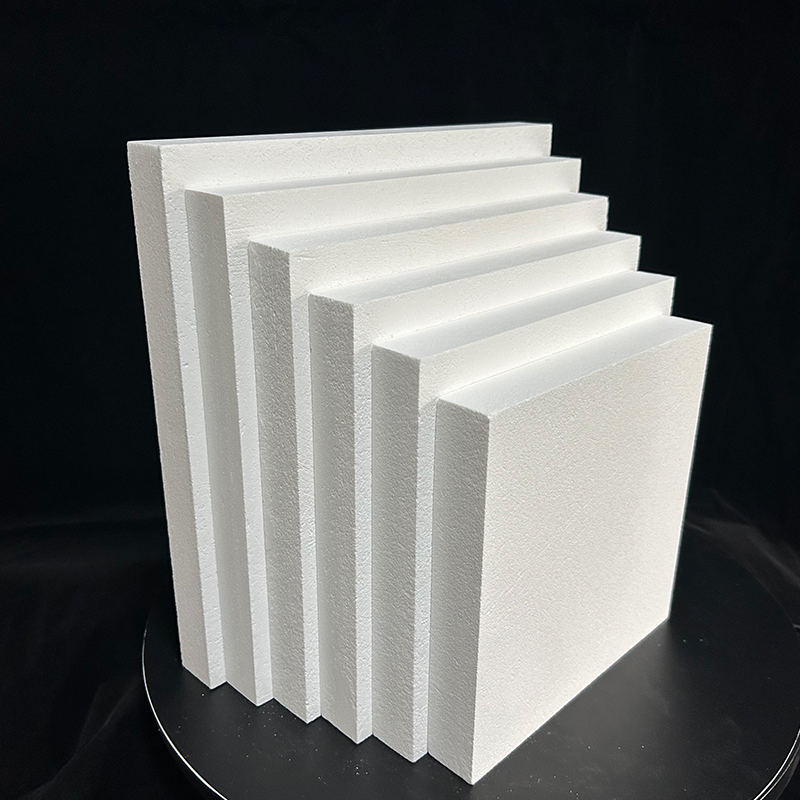

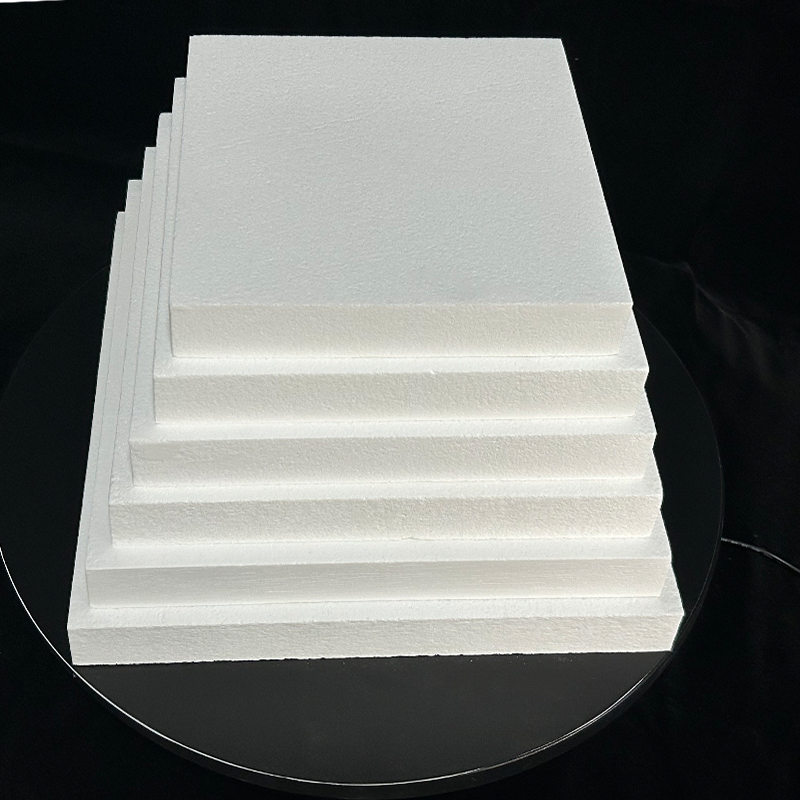

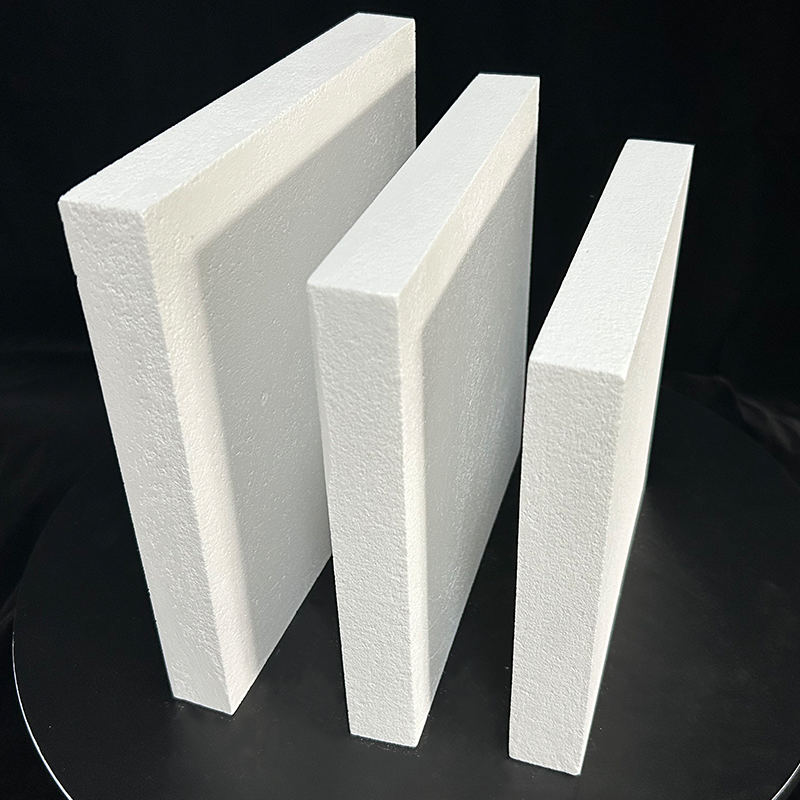

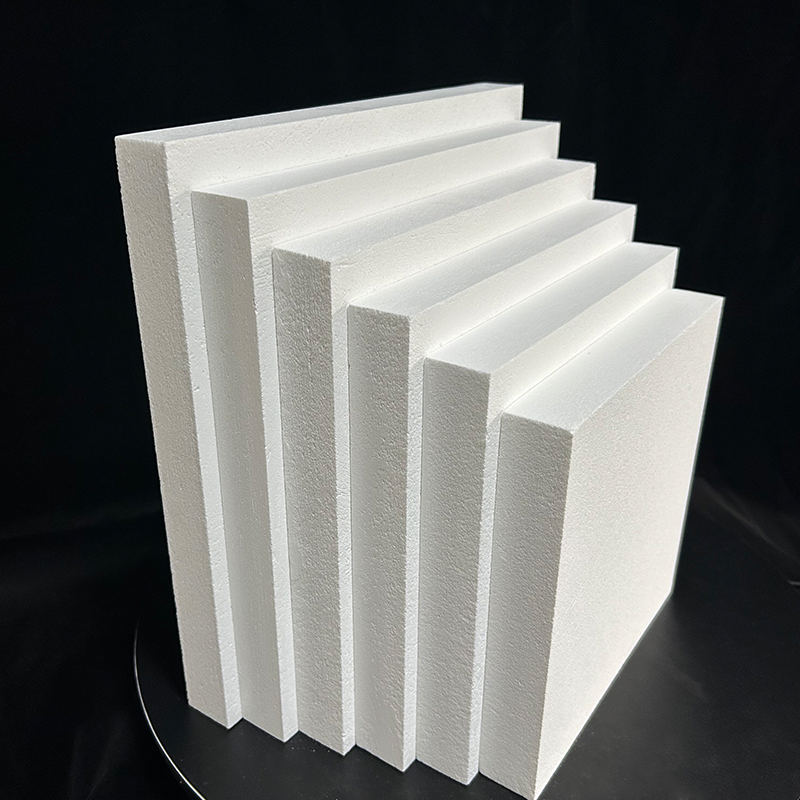

Alumina Ceramic Fiber Board

Introduction

NC Fiber Board is made of shattered cotton compressed together using inorganic adhesives by the wet vacuum suction filter process. With such advantages as low density and high intensity, the product has a wide range of applications, like as the hot surface of furnace lining to withstand the direct impact of flames and high-temperature gas glows.

Characteristics

High stability;

Low thermal conductivity;

Low thermal capacity;

Resistance to thermal shock;

Resistance to erosion;

Easy to process and cut;

High thickness precision and size precision;

Exceptional ability to withstand flames and gas flows;

Easy to install and convenient to use.

Application

Product parameter

|

Fiber Board |

NC1260 |

NC1350 |

NC1400 |

NC1430 |

NC1600 |

NC1700 |

NC1800 |

|

|

Classification Temperature(℃) |

1260 |

1350 |

1400 |

1430 |

1600 |

1700 |

1800 |

|

|

Density(KG/M³) |

300-600 |

300-600 |

300-600 |

300-600 |

300-600 |

450-700 |

450-700 |

|

|

Reheating Linearchange(%)(24H) |

≤1.5(1050℃ |

≤2.0(1100℃) |

≤3.0(1200℃ |

3.0(1250℃) |

≤1.0(1450℃) |

≤1.0(1500℃) |

≤1.0(1600℃) |

|

|

Flexural Strength(MPa) |

≥0.5 |

≥0.5 |

≥0.5 |

≥0.5 |

≥0.7 |

≥0.7 |

≥0.7 |

|

|

Lol |

≤5 |

≤5 |

≤5 |

≤5 |

≤6 |

≤6 |

≤6 |

|

|

Thermal Conductivity |

400℃ |

0.084 |

0.084 |

0.084 |

0.084 |

|

|

|

|

800℃ |

0.128 |

0.125 |

0.125 |

0.125 |

0.16 |

0.16 |

0.16 |

|

|

1000℃ |

0.176 |

0.174 |

0.174 |

0.2 |

0.21 |

0.21 |

0.21 |

|

|

|

Al₂O₃ |

45-49 |

52-55 |

54-57 |

44-48 |

72 |

78 |

83 |

|

Al₂O₃+SiO₂ |

98 |

99 |

99 |

82 |

99 |

99 |

99 |

|

|

ZrO₃ |

|

|

|

15-17 |

|

|

|

|

|

Other |

2 |

1 |

1 |

1 |

1 |

1 |

1 |

|

Note: The technical data determined by the testing standards used will, on average, fluctuate within a certain range; the data do not represent the product quality assurance data.

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى