Polycrystalline Mullite Fiber Veneer Block

Introduction

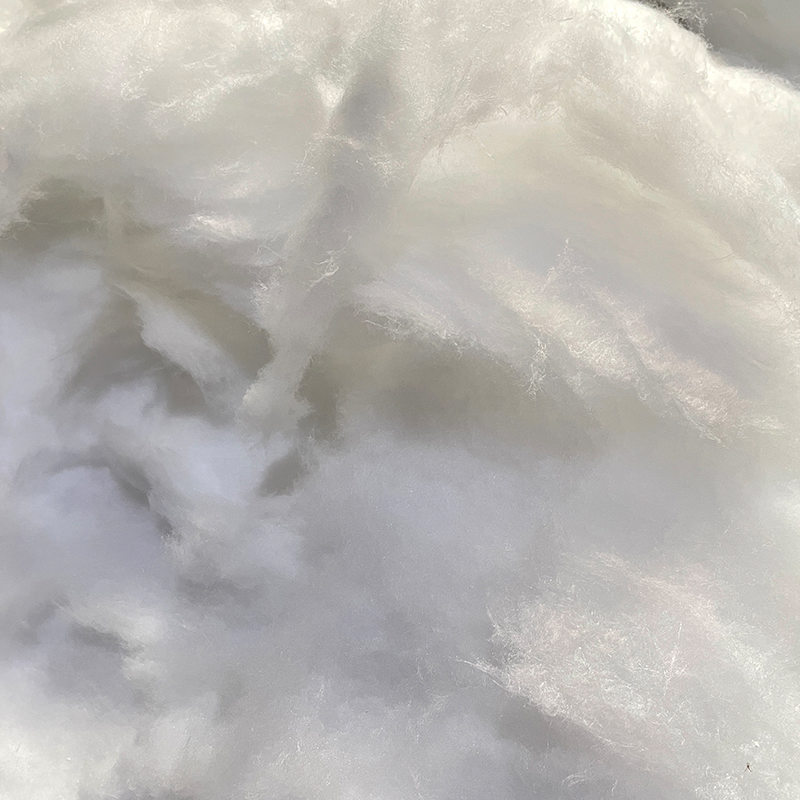

NC-1600 veneering Module is made of polycrystalline mullite fibers cut and compressed using special techniques. Containing no bonding agents or other materials, the module is known for its great elasticity and flexibility. Its temperature can reach 1600 °C. Even when constantly kept under this temperature, it still retains its original flexibility, strength, softness, and fiber structure, whether in oxidative, neutral, or reducing atmosphere. In addition, the product contains no shots and can be glued to the inner linings on the hot surfaces of all sorts of high-temperature industrial kilns and furnaces. With its exceptional heat insulation capacity, the module may be justly regarded as an outstanding fruit of high-tech industrialization.

Characteristics

Low heat storage;

Low thermal conductivity;

Resistance to thermal shock;

Excellent sound-absorbing capacity;

High heat reflection rate;

Even fiber diameter;

Great chemical stability;

Ability to withstand gas flow.

Application

Heating furnace;

Thermaltreatment furnace;

Shuttle kiln;

Tunnel kiln;

Roller kiln;

Furnace door;

Furnace cover sealing.

Common product specifications

200X 100X ( 30-100 ) mm

Product parameter

| Model | Classification temperature | Al2O3 | SiO2 | Density (KG/M3) |

Thermal conductivity (W/m.k) |

Reheating Linear change | Fiber diameter | Heat capacity | Melting point |

| NC-1600 | 1600°C | 72-75% | 25- 28% | 100 | 1000-0.226 1200-0.295 1300-0.337 1400-0.387 |

1500X6h<1% | 3-5 | 1024kj/kg.k | 1840°C |

| NC-1700 | 1700°C | 95% | 5% | 100 | 1000-0.226 1200-0.295 1300-0.337 1400-0.387 |

1600X6h<1% | 3-5 | 1024kj/kg.k | 1840*C |

Note: The technical data determined by the testing standards used will, on average, fluctuate within a certain range, the data do not represent the product quality assurance data.

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى