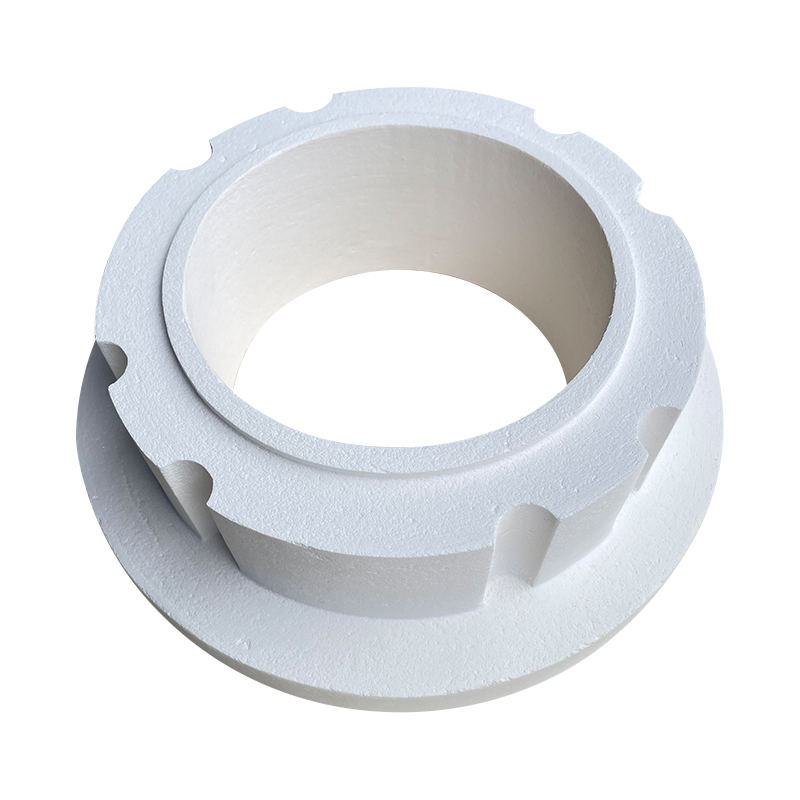

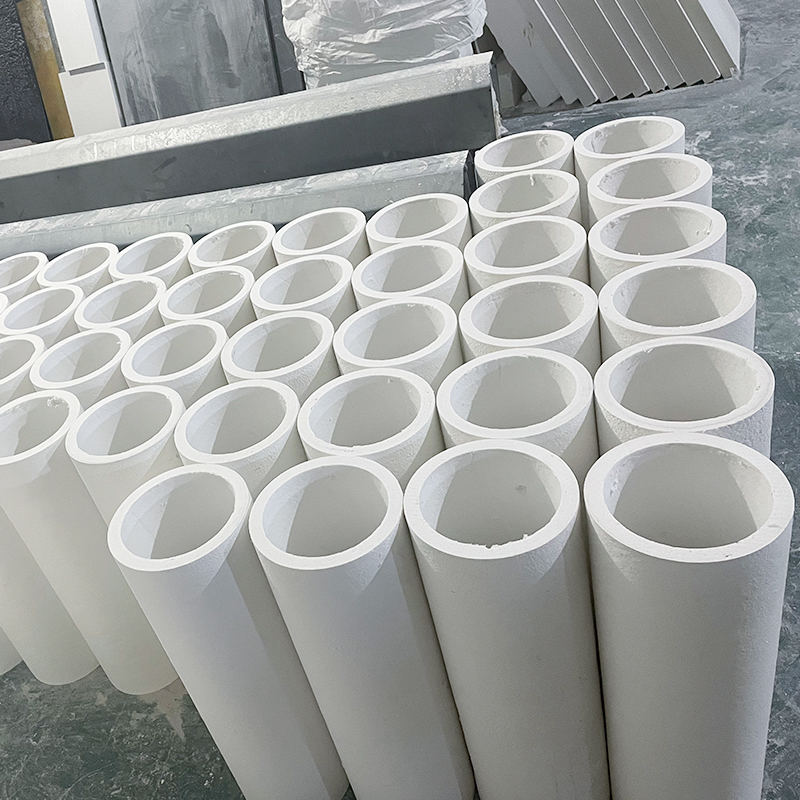

Ceramic Fiber Special Shaped Products(Customized according to drawings)

Introduction

Characteristics

compressive strength, bending resistance, low thermal conductivity, thermal shock resistance, high dimensional accuracy, rapid heating and cooling response, resistance to air flow erosion as well as tolerance for sudden temperature changes.

Application

Product Common Specifications

Customized according to the user's drawing or designed and produced by our company.

Product parameter

| Model | NC1260 | NC1350 | NC1400 | NC1430 | NC1600 | NC1700 | NC1800 | |

| Classification Temperature(℃) | 1260 | 1350 | 1400 | 1430 | 1600 | 1700 | 1800 | |

| Density(KG/M³) | 300-600 | 300-600 | 300-600 | 300-600 | 300-600 | 450-700 | 450-700 | |

| Reheating Linear Change(%)(24H) | ≤1.5(1050℃) | ≤2.0(1100℃) | ≤3.0(1200℃) | ≤3.0(1250℃) | ≤1.0(1450℃) | ≤1.0(1500℃) | ≤1.0(1600℃) | |

| Flexural Strength(MPa) | ≥0.5 | ≥0.5 | ≥0.5 | ≥0.5 | ≥0.7 | ≥0.7 | ≥0.7 | |

| Lol | ≤5 | ≤5 | ≤5 | ≤5 | ≤6 | ≤6 | ≤6 | |

| Thermal Conductivity (W/m.k) | 400℃ | 0.084 | 0.084 | 0.084 | 0.084 | |||

| 800℃ | 0.128 | 0.125 | 0.125 | 0.125 | 0.16 | 0.16 | 0.16 | |

| 1000℃ | 0.176 | 0.174 | 0.174 | 0.2 | 0.21 | 0.21 | 0.21 | |

| Chemical composition (%) | Al₂O₃ | 45-49 | 52-55 | 54-57 | 44-48 | 72 | 78 | 83 |

| Al₂O₃+SiO₂ | 98 | 99 | 99 | 82 | 99 | 99 | 99 | |

| zrO₃ | 15-17 | |||||||

| Other | 2 | 1 | 1 | 1 | 1 | 1 | 1 | |

Note: The technical data determined by the testing standards used will, on average, fluctuate within a certain range; the data do not represent the product quality assurance data.

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى