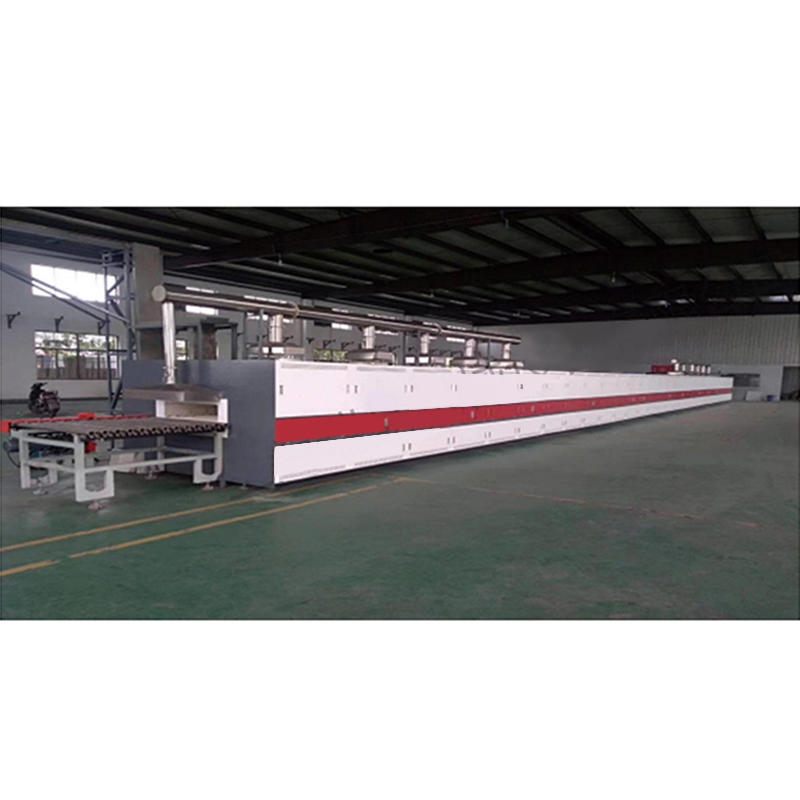

Roller Kiln

The workpiece can be placed directly on the roller, or the blank can be placed on the pad first, and then the hot plate can be placed on the roller. As the roller rotates continuously, the workpiece can be moved forward in sequence. There is a small sprocket at the end of each roller, which is driven by the chain to rotate. In order to ensure smooth and safe transmission, the strips are often divided into several groups for transmission. The rotation of the rollers allows the ceramics to be transferred from the kiln head to the kiln tail. It is mainly used in the production of ceramic building materials such as tiles, electronics, electromechanics, chemicals, equipment, printing, pharmaceuticals, industry, rubber, auto parts, moisture drying, and new energy batteries, etc.

| Furnace size (mm) | Maximum temperature(℃) | Stick Material | Power(KW) | Voltage | Heating method | Conveying speed |

| 15000*1000*1480 | 1000℃ | High Aluminum Tube/Silicon Carbide Tube | 125 | Three-phase five-wire 380V | Spiral resistance wire | 50-500MM/MIN(Adjustable) |

-

1、 Shaped ceramic fiber furnace lining for high alumina ceramic fiber board The shaped ceramic fiber furnace lining of high alumina ceramic fiber board mainly refers to the furnace lining composed of formed refractory materials such as fiber blankets, fiber felt, fiber boards or fiber components. Structurally, it can be divided into two categories: layered structure and composite structure. 1. Structure of Layered Refractory Fiber Lining Layered laying of refractory fiber furnace lining is...

English

English Español

Español عربى

عربى