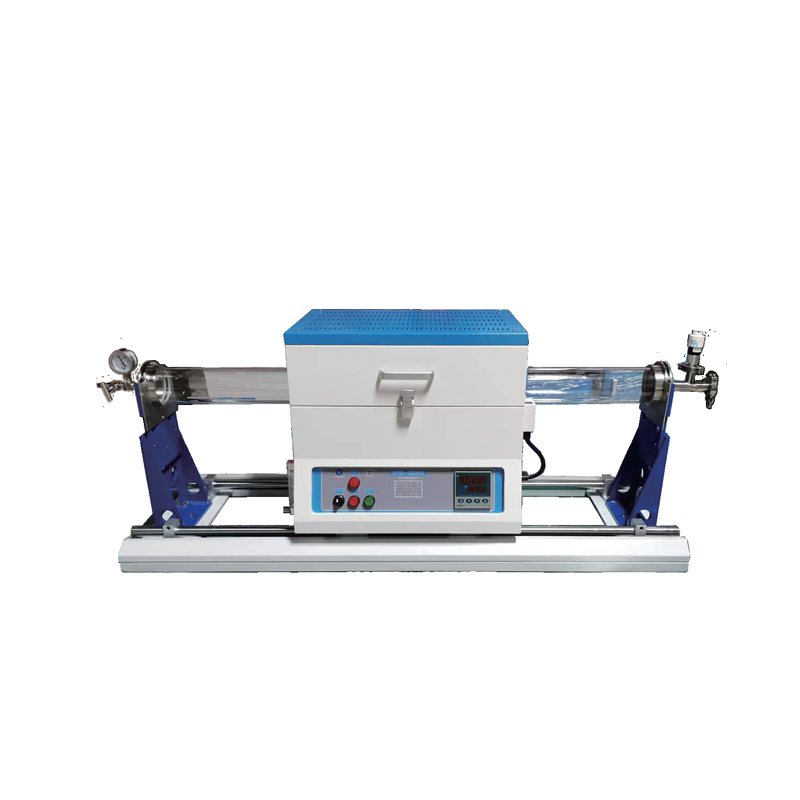

1200°C Sliding Tube Furnace

This equipment is a sliding tube furnace with a maximum operating temperature of up to 1200℃; it adopts a double-layer shell structure with an air cooling system; the furnace is made of high-purity alumina fiber material to minimize energy loss; the inner furnace surface is coated with a high-temperature alumina coating imported from the United States, which can improve the reflectivity and heating efficiency of the equipment, and also extend the service life of the instrument. The power is cut off when the door is opened, which improves experimental safety; a pair of slide rails are installed at the bottom of the furnace, which allows the furnace to slide from one side of the furnace tube to the other side for rapid heating and rapid cooling; for the fastest heating, the heating furnace can be preheated to the required temperature and then slid to the sample position; for the fastest cooling, the furnace can be slid to the other side after the sample heating is completed to achieve rapid cooling. It is an ideal equipment for low-cost rapid heat treatment.

Product Parameters:

· Maximum Operating Temperature: 1200°C (<0.5h)

· Continuous Operating Temperature: ≤1100°C

· Recommended Heating Rate: ≤10°C/min

· Heating Element: Iron-chromium-aluminum alloy wire

· Thermocouple: Type K

· Temperature Control Accuracy: ±1°C

· Temperature Control Method: Includes an intelligent temperature controller with PID control and auto-tuning, intelligent 30-50 programmable control, and over-temperature and burnout alarms.

· Certification Standards and Core Components: ISO9001 and CE Certification

· Core components include Chint and Schneider electrical components, UL-certified wire and cable, and Japanese, Yuden, and Eurotherm instrumentation.

| Specifications | Maximum temperature | Heating zone length | Quartz tube size | Rated power | Rated voltage | Dimensions | Weight |

| HGL1200 | 1200℃(<0.5 h) | 440mm | Φ25*1400mm | 3KW | 220V | 1680mm*490mm*700mm | About 75KG |

| Φ50*1400mm | |||||||

| Φ60*1400mm | |||||||

| Φ80* 1400mm | |||||||

| Φ100*1400mm | |||||||

| HGL1200 - Ⅱ | 1200℃(<0.5 h) | Dual temperature zones 200mm + 200mm | Φ25*1400mm | 3KW | 220V | 1680mm*600mm*630mm | About 75KG |

| Φ50*1400mm | |||||||

| Φ60*1400mm | |||||||

| Φ80* 1400mm | |||||||

| Φ100*1400mm |

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى