Ceramic Fiber Modules

Introduction

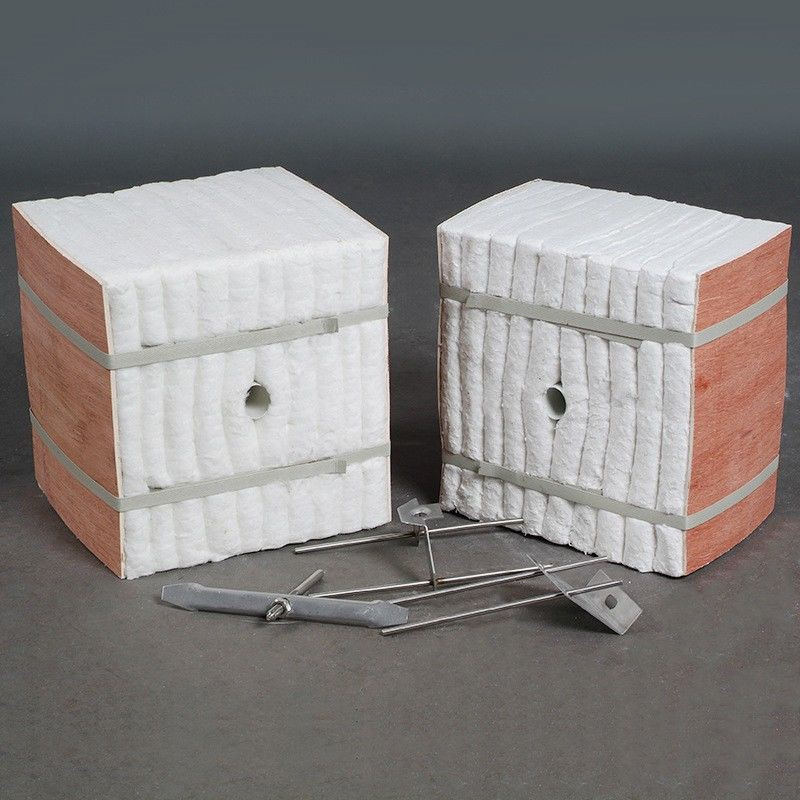

The NC ceramic fiber module is made of a ceramic fiber blanket, which is folded or cut by experienced professional technicians. It uses special equipment for producing modules to confirm the precise dimensions and keep a smooth surface module, designed for various thermal furnaces. The products have some characteristics, such as reliable quality, quick installation, and superior insulation properties.

The NC ceramic fiber module uses the enhanced M-type anchors, which have greater strength, closer to the cold face. It can ensure strength in high temperatures. The fixed link was welded together with high-quality heat-resistant steel and a stamped butterfly plate. The two round fixed links were embedded in the module system, enlarged the bearing area, and ensured the firmness of the anchor system.

Characteristics

low bulk density, low thermal conductivity; Resistance to heat-shock, ability to resist the scouring of airflow. Excellent chemical strength; built-in anchor, safety

performance; Easy to install, after installing the lining forms a seamless space, good insulation effect.

Application

Tunnel kiln, shuttle kiln, roller kiln; Atmospheric furnace, transforming furnace, coking furnace, cracking furnace, flue, etc; Ladle cover, annealing furnace, rotary

furnace, bell furnace, walking beam furnace, hot air and fluepipes, etc; Waste incinerators, RTO exhaust treatment furnace, SCR environmental catalytic stove, etc.

Product Common Specifications

(300-600)*300*(150-300)mm Other specifications according to customer's inquires.

|

Model |

NC1260 |

NC1350 |

NC1400 |

NC1430 |

NC1600 |

|

|

Classification temperature(℃) |

1260 |

1350 |

1400 |

1430 |

1600 |

|

|

Reheating linear change(%)192kg/m3/at()℃(24H) |

≤1.5(1000℃) |

≤1.3(1100℃) |

≤1.3(1200℃) |

≤1.5(1250℃) |

≤1.2(1450℃) |

|

|

Volume density(KG/m³) |

180-260 |

180-260 |

180-260 |

180-260 |

180-260 |

|

|

|

400℃ |

0.08 |

0.08 |

0.08 |

0.08 |

|

|

600℃ |

0.12 |

0.12 |

0.12 |

0.12 |

0.12 |

|

|

800℃ |

0.18 |

0.18 |

0.18 |

0.18 |

0.18 |

|

|

1000℃ |

0.25 |

0.25 |

0.25 |

0.25 |

0.25 |

|

|

1200℃ |

|

|

0.3 |

0.3 |

0.34 |

|

|

Chermical |

Al₂O₃ |

45-49 |

52-55 |

54-57 |

35-38 |

72-75 |

|

Al₂O₃+SiO₂ |

99 |

99 |

99 |

99 |

99 |

|

|

ZrO₃ |

|

|

|

15-17 |

|

|

|

Other |

1 |

1 |

1 |

1 |

1 |

|

Note: The technical data determined by the testing standards used will, on average, fluctuate within a certain range; the data do not represent the product quality assurance data.

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى