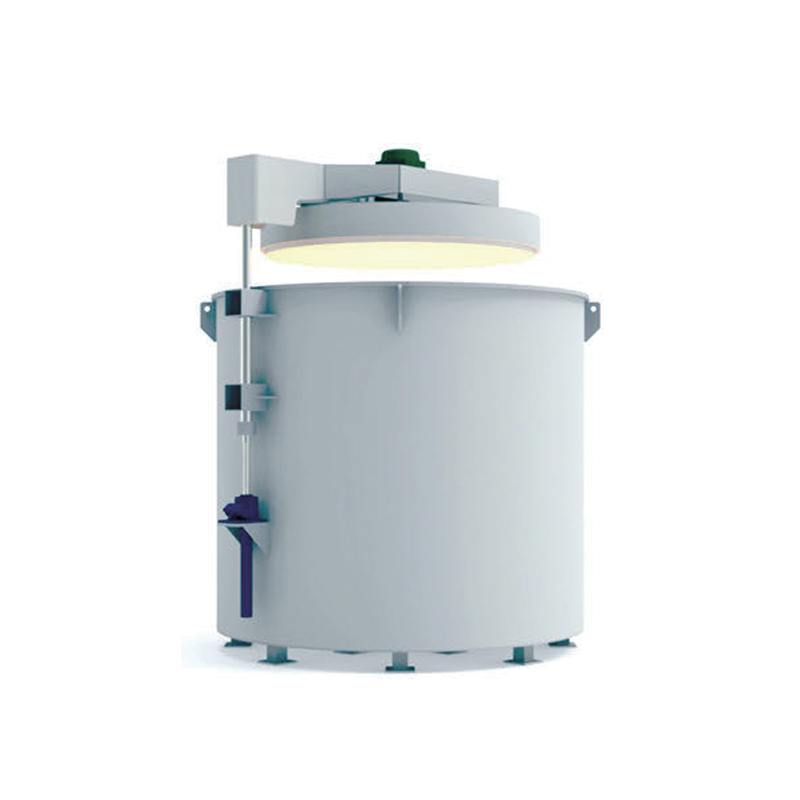

800°C 1000°C 1200°C 1500°C 1600°C Pit Furnace

Pit furnaces are widely used in ceramics, metallurgy, electronics, glass, chemicals, machinery, refractories, new materials development, specialty materials, and building materials.

Product Parameters:

● Furnace Net Dimensions: 800mm Diameter, 1500mm Height

● Heating Element: High-Temperature Alloy Resistance Wire (Molybdenum-Containing)

● Control Method: Multi-Channel Integrated Synchronous Control

● 3 temperature control points and 9 temperature adjustment zones, using distributed synchronous control to achieve uniform temperature within the furnace

● Furnace Internal Temperature Uniformity: 800mm ±1°C; 1300mm ±5°C

● Microcomputer control for easy operation; programmable, automatic temperature rise, automatic hold, and automatic temperature reduction

● Fast heating (heating rate 1-20°C/min) Adjustable)

·Energy-saving (furnace chamber made of imported fiber, resistant to high temperatures and rapid heating and cooling)

·Furnace body is made of finely sprayed plastic for corrosion resistance and acid and alkali resistance, and the furnace temperature is close to room temperature, less than 40°C

·Dual-circuit protection (overtemperature, overpressure, overcurrent, short circuit, power failure, etc.)

·Furnace chamber made of imported refractory material, with excellent thermal insulation, high temperature resistance, and resistance to rapid heating and cooling

·Temperature range: 800°C, 1000°C, 1200°C, 1500°C, 1600°C

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى