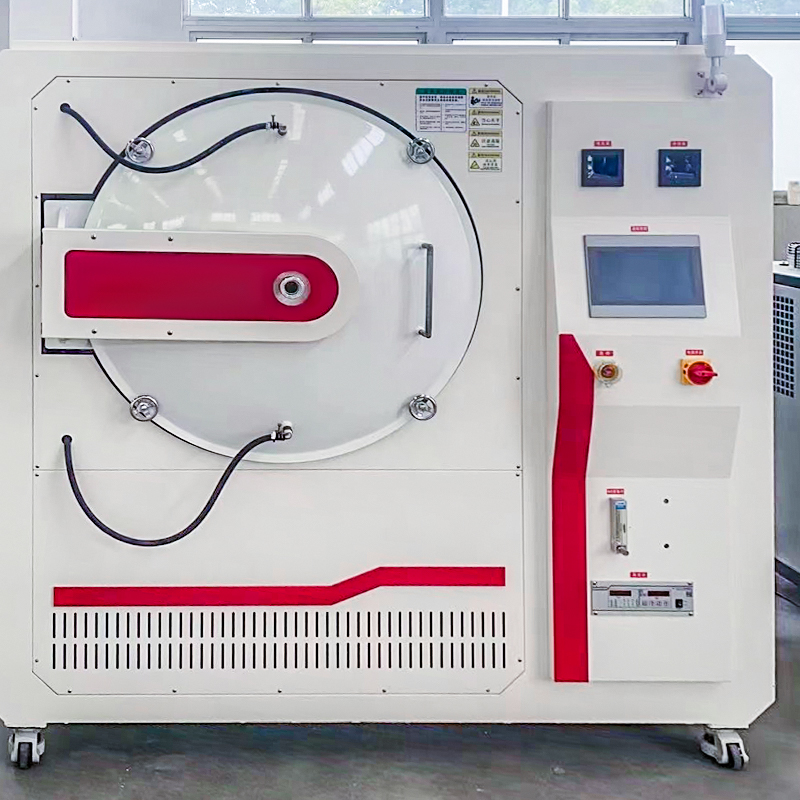

Low Temperature Vacuum Annealing Furnace

This equipment is a horizontal structure with a square structure in the middle of a circle, which can ensure high vacuum efficiency while also making the furnace resistant to deformation and durable. The finned metal tube is heated inside, and the heat is evenly distributed with a multi-layer heat insulation screen. The furnace uses a 304 stainless steel furnace and a carbon steel outer layer. The two layers are cooled with circulating water, which has a long service life. It is mainly used for ceramic firing, vacuum smelting, degassing of electric vacuum parts, annealing, brazing of metal parts, and ceramic-metal sealing.

| Furnace size (mm) | Maximum temperature (°C) | Power(KW) | Voltage | Heating elements | Heating rate | Vacuum degree |

| 400*300*300 | 600°C | 9 | 380V | Spiked heating tube | 1-20°C/MIN | 10PA |

| 500*400*400 | 12 | |||||

| 600*500*500 | 18 | |||||

| 800*500*500 | 27 |

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى