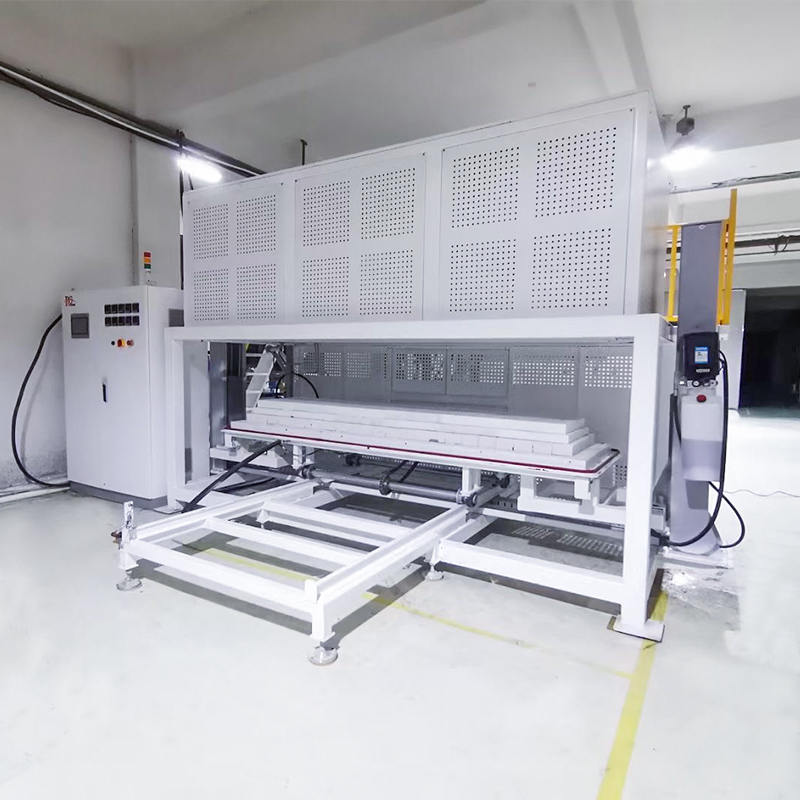

Industrial Lifting Sintering Furnace

This vertical vacuum carbon tube furnace uses graphite electrodes, which are connected to the graphite heating element by cylindrical contact. One end of each electrode extends out of the furnace through a seal. It is an important component that allows the current to pass to the heating element in the furnace. It is evenly heated and has good pressure resistance. There is a heat insulation screen device composed of multiple layers of radiation screens around the heating element. The inner layer of the furnace shell is stainless steel, and the outer layer is carbon steel. There is a water cooling system between the two layers. The shell temperature is <50℃℃, and high-temperature sintering can be achieved in a completely oxygen-free state. The furnace chamber uses ceramic alumina fiber, which has good thermal insulation performance and high cleanliness. It is widely used in the sintering preparation of inorganic materials (such as ceramic seals, silicon carbide, zirconium oxide, zinc oxide, aluminum dioxide, etc.) and metal materials (such as cemented carbide) in vacuum or protective atmosphere. It can also be used for the purification of rare earth elements and their oxides and sapphire annealing.

| Furnace size (mm) | Maximum temperature(℃) | Heating elements | Power(KW) | Voltage | Heating rate |

| φ1000*1000*1000 | 1200℃ | Resistance wire | 110 | 220/380V | 1-20℃/MIN |

| φ1850*700*600 | 1400℃ | Silicon Carbon Rod | 90 | ||

| φ1350*600*600 | 75 | ||||

| φ2400*800*800 | 185 | ||||

| φ1000*1000*1000 | 120 | ||||

| φ1100*1000*1000 | 105 | ||||

| φ500*500*500 | 1700℃ | Silicon molybdenum rod | 35 | ||

| φ800*500*500 | 60 | ||||

| φ1350*500*500 | 80 | ||||

| φ2400*500*500 | 150 | ||||

| φ2400*700*700 | 220 |

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى