Porous vacuum silicon heat insulation cotton

Super Insulation Wool is a new thermal insulation material made of cross-linked sheets of polymer material and nanoporous vacuum silica. The nanoporous vacuum silica has a pore diameter of 10-40 nm, smaller than the mean free path of air molecules (68 nm). It boasts a porosity of over 97% and a density as low as 0.03 g/m², achieving a near-vacuum-like effect. This prevents molecular collisions within the pores, resulting in exceptionally high thermal insulation performance.

Thermal insulation wool is a flexible sheet insulation material made by combining porous oxidized vacuum silica with a polymer skeleton through a vacuum cross-linking, vaporization, and high-pressure drying process. Its porous structure and uniform surface offer a thermal conductivity as low as 0.014 W/m·K. It also possesses excellent properties such as hydrophobicity, flame retardancy, insulation, and environmental friendliness. It addresses the thermal insulation challenges of electronic products in confined spaces while also enhancing user comfort. Compared to traditional insulation materials, its lower thermal conductivity makes it ideal for use in electronic products and applications such as aerospace, smart handheld devices, smart wearables, e-cigarettes, wireless chargers, power supplies, small appliances, and large equipment.

Product features:

1.Ultra-low thermal conductivity, down to 0.014 W/(m·K).

2.Adjustable thickness, customizable from 0.5 to 4 mm.

3.Adjustable form, customizable in rolls or sheets.

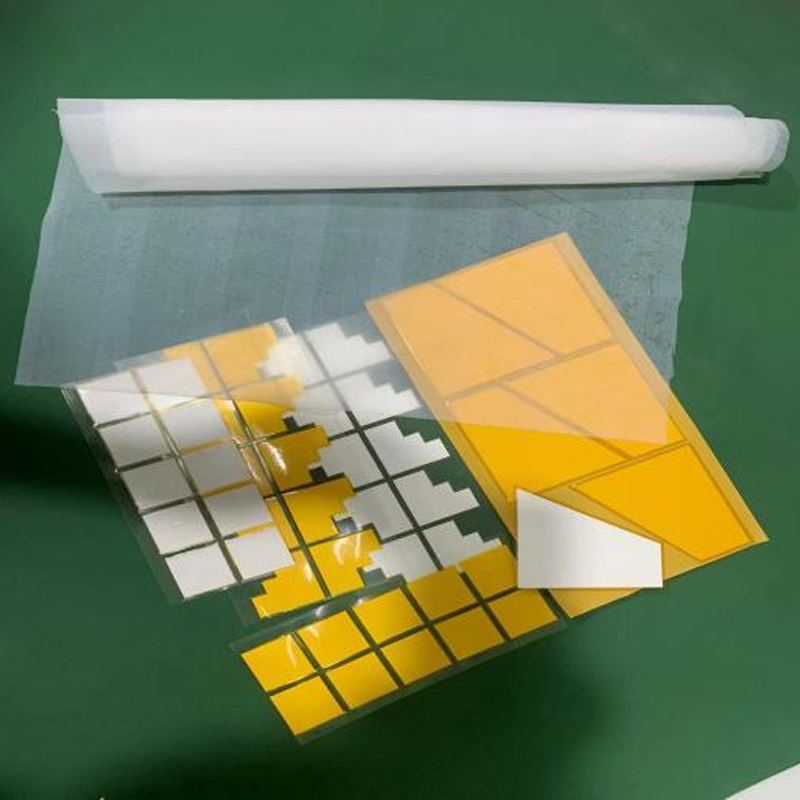

4.Direct die-cutting, edge wrapping, and lamination with double-sided tape/film are available, allowing for custom cutting according to customer specifications.

5.Can be combined with our thermally conductive graphite film and nano-carbon copper composite materials.

6.Compliant with the R0SH environmental directive.

Product applications:

Aerospace, e-cigarettes, battery energy storage, power battery module spacers, wearable devices, home appliances, smart terminals, smart TV screens, laptops, heating elements, and thermal insulation for mechanical equipment.

MGF thermal insulation cotton product parameters

| Items & Properties | MGF500/1000/1500/2000/2500/3000/3500/4000 | Testing standards |

| Thickness(mm) | 0.5/1.0/1.5/2.0/2.5/3.0/3.5mm/4.0mm | ASTM D374 |

| Thermal conductivity | 0.014-0.017W/m·K | ASTM D5470/TPS |

| Continuous Use Temp(°C) | -240 | Standard |

| Dielectric Constant(KHz) | 5.5 | ASTM D149 |

| Flammability Rating | V-O Equivalent | UL94 |

| Total Mass Loss(wt%) | 0.020+/-0.002 | ASTM E595 |

| Volatile Condensable Material(wt%) | 0.040±0.001 | ASTM E595 |

| Water Vapor Recovered(wt%) | 0.010±0.001 | ASTM E595 |

| Volume Resistivity (Ohm-meter) | ≥1.0x10¹³ Ωcm | ASTM D257 |

| Hydrophobicity | 99.40% | GB/T10299 |

| Water absorption | 1.40% | GB/T5480 |

Thermal insulation test structure:(Environmental 25±1℃/50±20%RH)

| Heating platform heat source surface temperature/constant temperature (°C) | 1mm insulation cotton constant temperature after thermal equilibrium (°C) | 2mm insulation cotton constant temperature after thermal equilibrium (°C) | 3mm insulation cotton constant temperature after thermal equilibrium (°C) | 4mm insulation cotton constant temperature after thermal equilibrium (°C) |

| 100 | 66 | 53 | 43 | 39 |

| 200 | 116 | 99 | 82 | 67 |

| 300 | 167 | 134 | 114 | 96 |

MGF insulation cotton product compression test: ASTMD1056-14

| thickness | 20% compressive stress (psi) | 50% compressive stress (psi) | 75% compressive stress (psi) | 90% compressive stress (psi) |

| 2.0mm | 10.2 | 54.1 | 358.2 | 1917 |

| 3.0mm | 8.18 | 36 | 254 | 1944 |

| 5.0mm | 6.54 | 28.8 | 215 | 1794 |

-

Overview of High Temperature Muffle Furnaces High temperature muffle furnaces are specialized laboratory equipment designed to provide uniform and controlled heating environments. They are widely used in materials research, metal processing, ceramics, and chemical laboratories. Unlike conventional furnaces, muffle furnaces isolate the material from the direct flame or heating elements, reducing contamination and ensuring precise thermal processing. Key Features of High Temperature Muffle Furnace...

English

English Español

Español عربى

عربى